The automotive wiring harness is an essential part of any vehicle, functioning as the central nervous system that connects all electrical components. Without it, modern vehicles would not be able to operate the myriad of systems we rely on today, such as engine controls, infotainment, lighting, and safety features. In this article, we will dive deep into the structure, functions, and importance of automotive wiring harnesses, exploring why they are vital to the automotive industry and how they are shaping the future of automotive technology.

An automotive wiring harness is a carefully organized bundle of wires, terminals, connectors, and insulating materials designed to distribute power and transmit electrical signals throughout a vehicle. These harnesses connect various electrical components, such as the engine, transmission, lights, and infotainment system, ensuring that all systems work harmoniously.

Wiring harnesses are engineered to withstand harsh automotive environments, including extreme temperatures, vibrations, and exposure to chemicals. As vehicles become more complex with the integration of advanced technology, the role of the automotive wiring harness has expanded significantly.

Understanding the components of a wiring harness is essential to appreciate its complexity and importance. A typical automotive wiring harness includes:

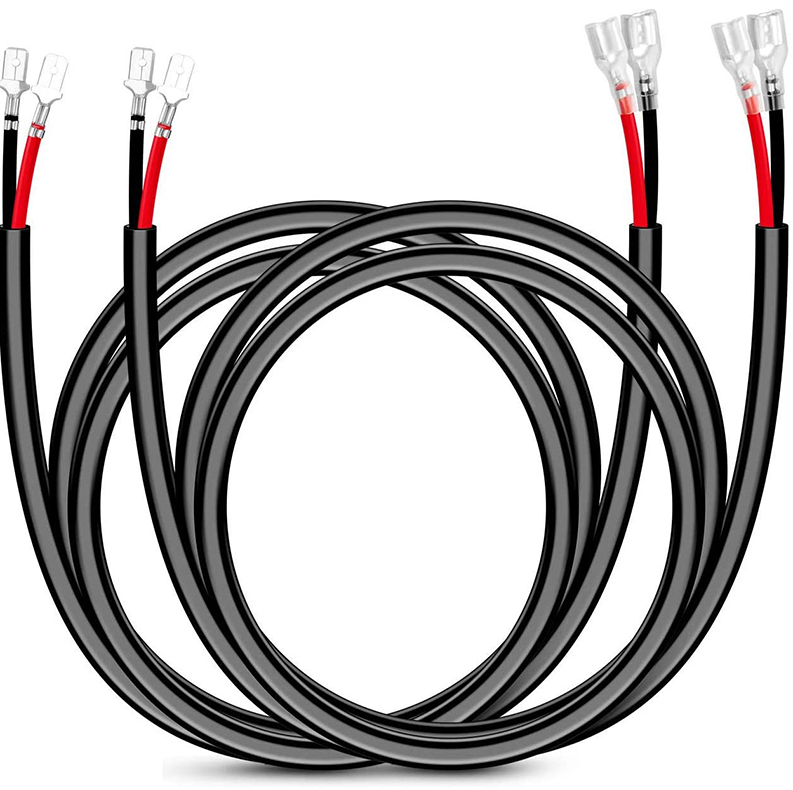

The backbone of the harness, wires and cables are made of conductive materials like copper or aluminum. These conduct electricity between various components of the vehicle. Wires are insulated to protect them from environmental damage and to prevent short circuits.

Connectors join the wires to different components of the vehicle. They are designed to fit securely and ensure that power and signals are transmitted without any interruptions. Automotive connectors are often waterproof and vibration-resistant to ensure longevity and reliability.

Terminals are the end points of the wires that connect to the various electrical components. They are crucial for establishing a secure and stable electrical connection. Terminals are usually made from highly conductive metals, ensuring minimal energy loss.

Wiring harnesses are covered with various insulation materials to protect them from external factors such as heat, moisture, and chemical exposure. The insulation also helps organize the wires and cables within the harness, ensuring they don’t get tangled or damaged.

To further safeguard the wiring harness, protective covers and tubes are used. These provide additional protection from physical damage, wear and tear, and environmental exposure. They are often made of durable materials like plastic, rubber, or metal.

Automotive wiring harnesses are tailored for specific vehicle functions and can be categorized based on their application:

The engine wiring harness connects all the critical components in the engine bay, such as the alternator, starter motor, and sensors. This type of harness ensures that the engine operates smoothly and that all performance-related components are functioning correctly.

The body wiring harness controls non-engine components, such as lighting, door locks, and infotainment systems. It is responsible for the proper functioning of features that improve the driver's and passengers' comfort and convenience.

The chassis wiring harness is designed to connect systems related to the vehicle's suspension, transmission, and brake controls. These harnesses are crucial for the vehicle's overall drivability and safety.

The HVAC wiring harness is responsible for controlling the heating, ventilation, and air conditioning systems in the vehicle. It ensures that the temperature control functions work seamlessly, maintaining a comfortable environment inside the cabin.

The battery cable harness connects the vehicle's battery to the electrical system. This harness provides the primary power supply to start the vehicle and operate all electrical components.

A well-designed automotive wiring harness is vital to the overall performance and safety of a vehicle. Its importance cannot be overstated:

By efficiently transmitting power and signals, the wiring harness ensures that all vehicle systems perform optimally. A poorly designed harness can lead to power losses, signal interruptions, and malfunctions.

The safety of a vehicle largely depends on its electrical systems, such as airbags, anti-lock brakes, and electronic stability control. A wiring harness that is designed to meet rigorous standards ensures that these safety features operate without fail.

Automotive wiring harnesses are designed to be modular, meaning that if one component fails, it can be replaced without disturbing the entire system. This modularity simplifies the maintenance and repair process, saving both time and money for vehicle owners.

Modern wiring harnesses are designed to be lightweight and compact, which contributes to overall vehicle efficiency. By reducing weight, automotive manufacturers can improve fuel efficiency, while compact designs free up space for other components.

Automotive wiring harnesses are customizable to fit the specific needs of a vehicle's design. This flexibility allows manufacturers to integrate new technologies, such as advanced driver assistance systems (ADAS) and electric vehicle components, without having to redesign the entire vehicle.

The design and manufacturing of automotive wiring harnesses come with several challenges:

As vehicles become more technologically advanced, the number of electronic systems integrated into them increases. This rise in complexity demands more sophisticated wiring harness designs that can handle higher electrical loads without failure.

Automotive wiring harnesses must withstand extreme environmental conditions, including temperature fluctuations, exposure to chemicals, and mechanical stress. Designing a harness that can endure these conditions while maintaining optimal performance is a significant challenge.

Manufacturing wiring harnesses that meet stringent safety and performance standards can be expensive. Automotive manufacturers must balance cost-effectiveness with quality to ensure that their vehicles remain affordable without compromising on safety or reliability.

As automotive components continue to shrink in size, so too must the wiring harnesses. The challenge lies in maintaining the same level of functionality and durability while reducing the size of the harness components.

The future of the automotive wiring harness is closely tied to the rise of electric vehicles (EVs) and autonomous driving technologies. As vehicles transition from internal combustion engines to electric powertrains, wiring harnesses will need to evolve to handle higher electrical loads and integrate new systems like battery management, charging systems, and regenerative braking.

Autonomous vehicles will require even more complex wiring harnesses to support the vast array of sensors, cameras, and communication systems necessary for self-driving capabilities. Additionally, the push towards lighter and more efficient vehicles will drive innovation in materials and design, making future wiring harnesses more advanced than ever before.

Hong Kong Suntex specializes in OEM/ODM wiring harness solutions tailored to meet your specific requirements. Also referred to as cable harnesses, wire harnesses, or cable assemblies, these are integral assemblies of electrical cables and wires designed to transmit signals or electrical power efficiently.

Comments

Please Join Us to post.

0